I had the idea !

Contact:

Lista Studio srl®, Borgo Belvigo 33, 36016 Thiene Vi ITALY

www.ihadtheidea.com, tel/fax +39,0445,372479 -

info@ihadtheidea.com

CONVEE, a new endothermic engine

by Pierfrancesco Poniz, February 27th, 2015.

CONVEE - COMPACT NON-VIBRATING ENDOTHERMIC ENGINE

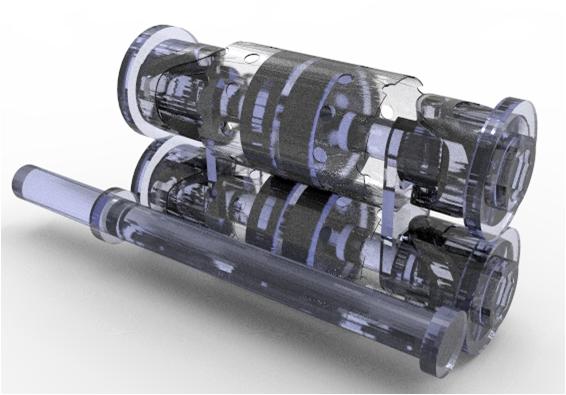

CONVEE (Compact Non Vibrating Endothermic Engine) is an internal combustion engine made of two cylinders realizing a two strokes uniflow scavenging cycle with an innovative kinematics design: a new mechanism to transform the alternative motion of two couples of opposing pistons into the rotation of only one shaft. The engine results very compact, lightweight and dynamically balanced.

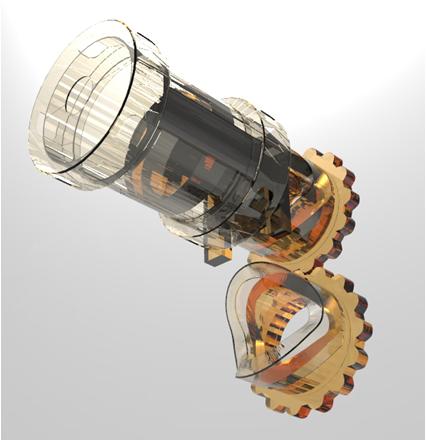

CONVEE is an internal combustion 2 cylinders axial engine, with 2 strokes uniflow scavenging cycle realized by 4 opposing pistons driven by 4 cylindrical cams coaxial with them.

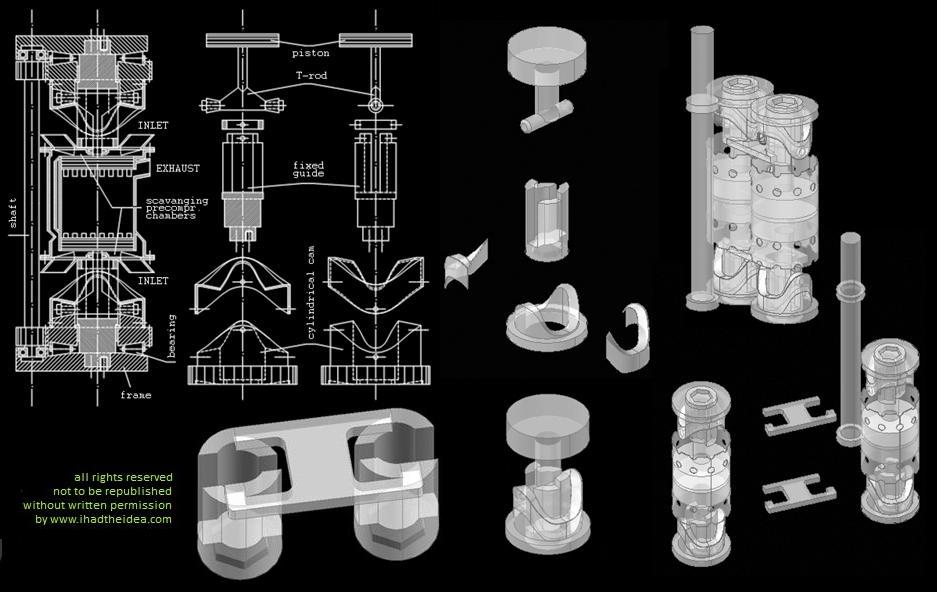

The fresh air pre-compression for scavenging is provided by each piston's backstroke in a specific, lubricating fluid-free chamber laying behind each piston and enclosed by a wall which closes each cylinder's end.

Each piston is driven in its oscillation movement through this wall by a cylindrical stem solidly fixed on its back, sliding through a circular hole in the center of said wall.

This stem forks into two equal arms heading in opposed direction and terminating each with a roller or the like. I call the ensemble of the stem and its arms 'T-rod'.

Said arms oscillate with the piston and slide through a guide which is solidly fixed to the frame so that binds them to simple oscillation and avoiding rotation around the cylinder's axis.

The arms' ends meet the two periods sinusoidal track of a hollow cylindrical cam, whose cavity houses said fixed guide and whose rotation axis coincides with the cylinder's axis: the other cylindrical cam's face lays against the frame, which binds it, through an axial bearing, to simple rotation around its axis, without oscillating like the piston which moves it.

The motor shaft is straight and has two synchronizer gears to its ends, the cylinders are parallel to it, and it synchronizes the motion of the cams at the inlet end with the cams at the exhaust end of each cylinder. Synchronized gears may be one piece with cylindrical cams, and each one of cylinder's inlet end's couple of cams and cylinder's exhaust end's couple of cams may be directly meshed through their gears.

This cinematic configuration allows to have:

All of these advantages lead to an internal combustion engine which in respect to those actually on the market is significantly smaller, lighter, cheaper and more sustainable, both by needing minor metal production and by lightening all the vehicle that is supposed to be moved, which will have better performances.

An international patent submission is established at UIBM, waiting for PCT at WIPO.